Autonecking Without The Bottlenecking

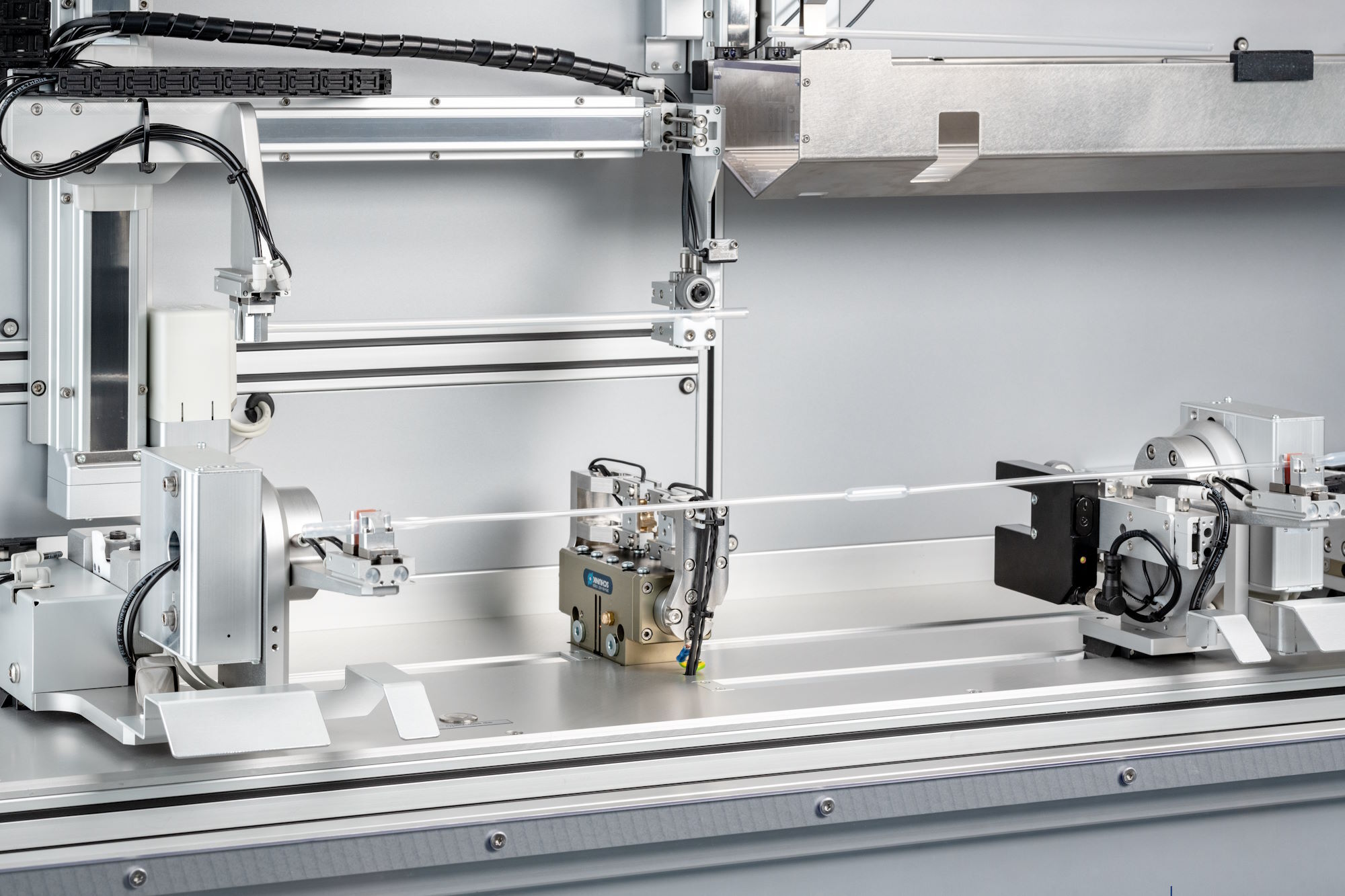

Introducing the Swiss-engineered BW-TEC 2711 Autonecker

Whether you're launching high-volume lines or closing production gaps, the 2711 brings repeatability, efficiency, and ROI into perfect alignment.

Minimal Labor. Maximum Output.

BW-TEC 2711 Autonecker

1,000+ Parisons. 9 Hours. Near-zero Labor.

Automate your balloon necking process with unmatched consistency and control. Designed for high-throughput production, the compact 2711 system ensures uniform necking results, every time, while minimizing operator input and reducing scrap.

-

Large 3,000-tray capacity - built to accommodate a range of extrusion and tubing sizes.

-

120 Parisons/hour – or ~1,000 per 9-hour shift.

-

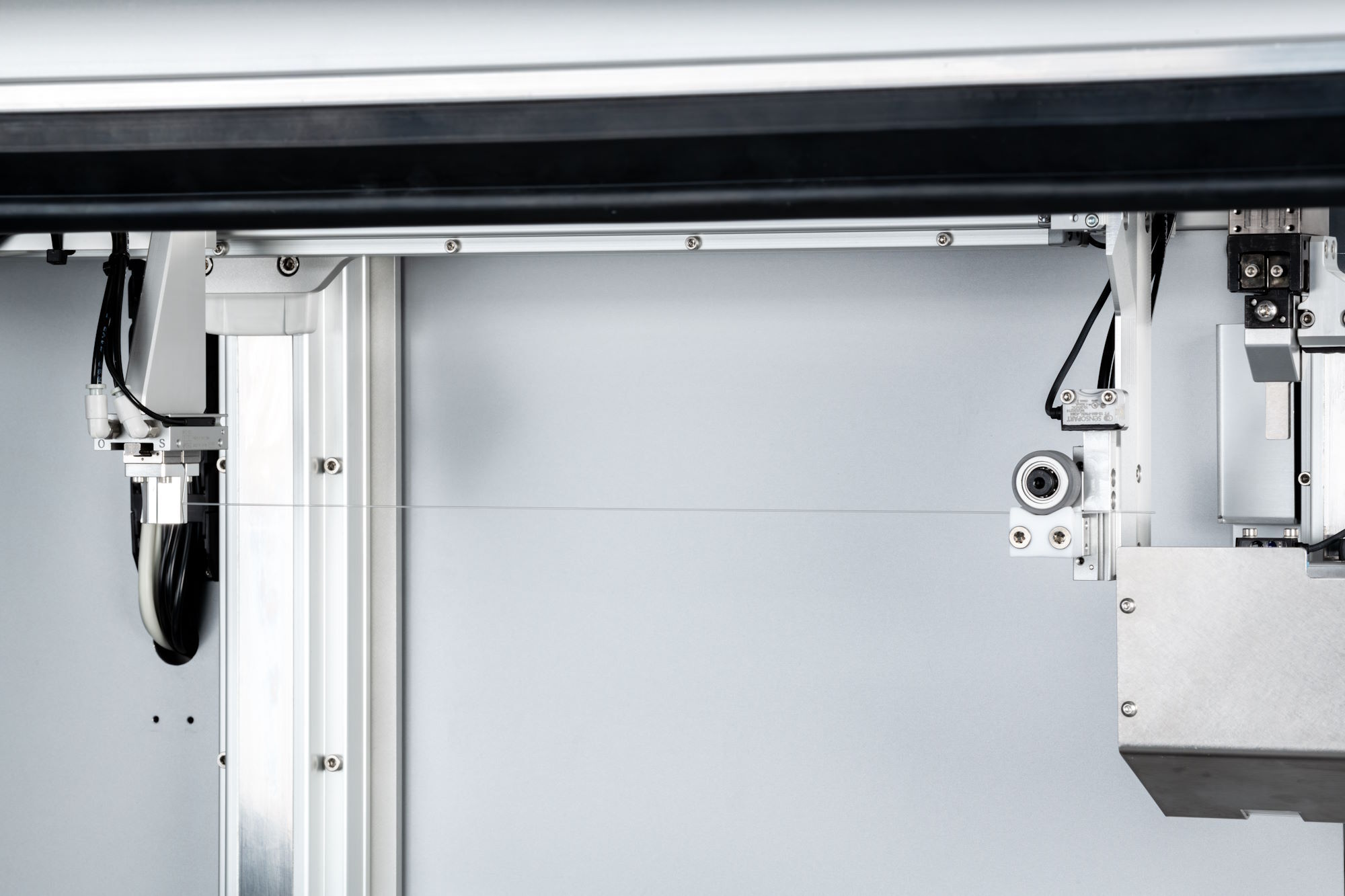

Vision alignment – ensures precise, repeatable parison length.

-

Fully automated – loads, clamps, necks, and transfers hands-free.

-

Touchscreen recipes – fast changeovers and consistent runs.

.jpg?width=1740&height=909&name=Machine%20Solutions%20logo02%20(2).jpg)